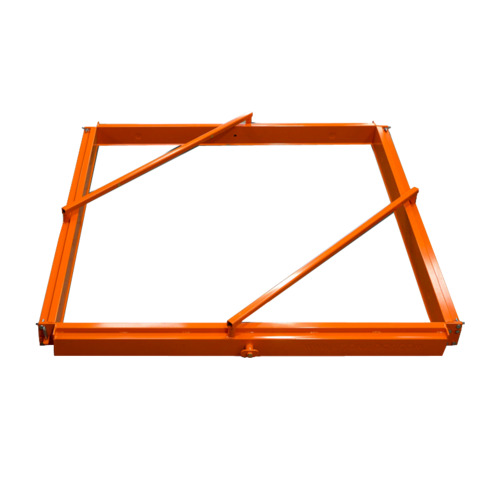

Check out our step-by-step instructions on how to pour the perfect concrete block and how to insert anchors. All our instructions are clear, highly detailed and come with photos and videos.

Betonblock worldwide.

Visit your website!

You are visiting us from the United States.

For local offers, support, and faster service, please visit our new

website specifically for the U.S.