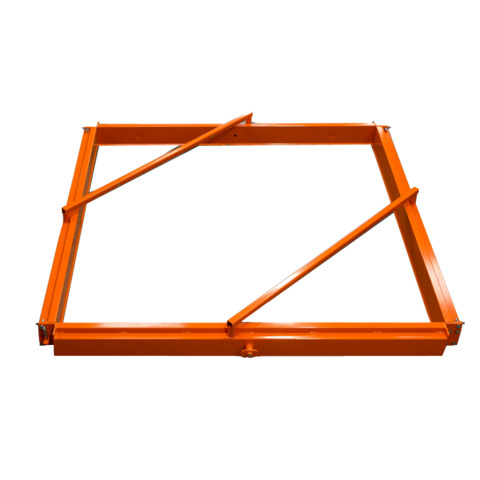

Check out our step-by-step instructions on how to pour the perfect concrete block and how to insert anchors. All our instructions are clear, highly detailed and come with photos and videos.

Continue with the currently selected region or select another region.